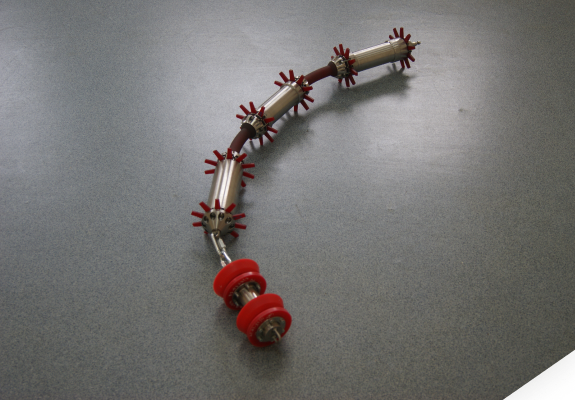

In-line defect indicator (EasyPig) - magnetic in-line inspection tool (EasyPig) for detecting defects and anomalies in steel pipelines of small diameter, including unauthorized taps.

BENEFITS:

- Low cost of examination due to the exclusion of excessive diagnostic information

- A design that allows you to examine pipelines inaccessible to traditional inspection devices

- Providing information on the location of unauthorized taps

| Technical characteristics | EasyPig 8” | EasyPig 6” | EasyPig 4” |

| Nominal pipe diameter | 8” | 6” | 4” |

| Device speed | 0,05 – 4 m/s | 0,05 – 4 m/s | 0,05 – 4 m/s |

| Pipe wall thickness | 6 - 12 mm | 6 - 10mm | 6 - 10mm |

| Internal diameter of the pipeline | 183 – 207 mm | 125 - 147mm | 84 – 102 mm |

| The minimum turning radius | 328.5mm | 238.5mm | 342mm |

In-line ultrasonic inspection device (EasyPig UT) is designed for non-destructive precise testing of field pipelines

BENEFITS:

- Available. The use of EasyPig UT provides a low cost of examinations.

- The ability to measure the thickness of the pipe wall and the protective and insulating coating allows you to calculate the residual durability and the term of safe operation of pipelines

- Diagnostics of pipes made of non-magnetic materials, including stainless steel

- Determination of the internal profile of the pipeline.

** EasyPig UT run is carried out only in single-phase medium (water, kerosine).

| Technical characteristics | EasyPig UT 8” | EasyPig UT 6” | EasyPig UT 4” |

| Nominal pipe diameter | 8” | 6” | 4” |

| Device speed | 0,05 – 0,1 m/s | 0,05 – 0,1m/s | 0,05 – 0,1 m/s |

| Pipe wall thickness | 6 - 22 mm | 6 - 25mm (6 – 15 mm) | 6 - 14mm |

| Internal diameter of the pipeline | 173 - 207mm | 122 – 147 mm (129 – 156 mm) | 84 – 102 mm |

| The minimum turning radius | 328.5mm | 238.5mm | 456mm |

Maximum speed - is directly proportional to the resolution and is determined by the maximum allowable resolution along the axis of the pipe.