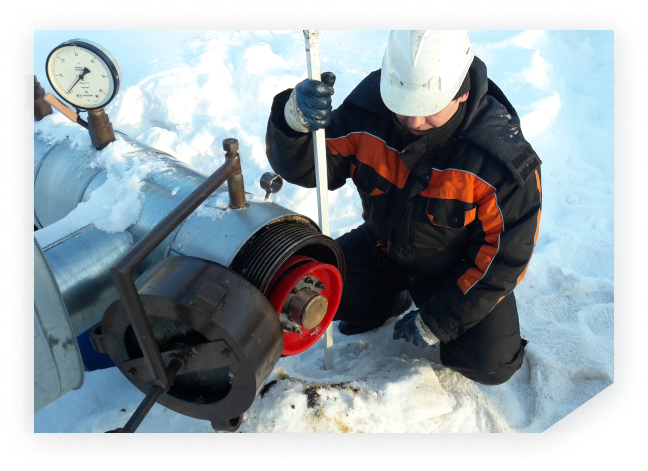

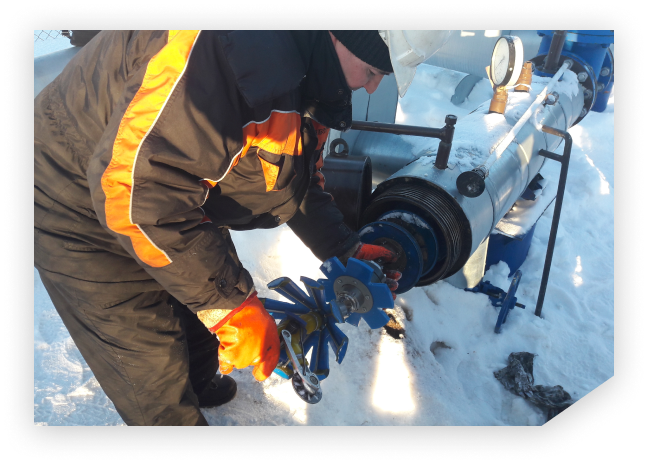

Identification of critical defects and anomalies in pipelines, including unauthorized taps. Before passing flaw detectors, engineers of INTRON VTD can carry out a full range of preparatory work, including cleaning, profilometry and calibration. The field report is issued within 3 days after an inspection. A full technical report is issued no later than 45 working days.

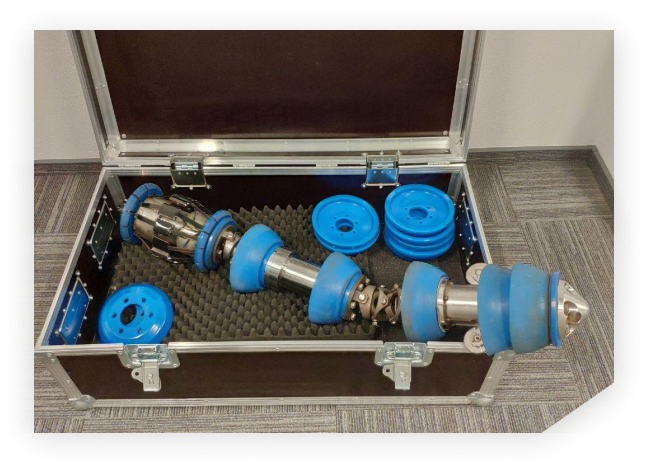

Granting for rent a complete set of equipment for carrying out inline inspection. The equipment comes with all the necessary supporting documentation. Interpretation of data is carried out by specialists of INTRON VTD LLC

The duration of employee training is 5 days. The qualification requirement for personnel undergoing training is certification of at least level II in the field of non-destructive testing methods.

Development of new devices in the field of inline inspection for specific goals and objectives of the enterprise. Production of prototypes and their testing.

Identification of defects in the geometry of the inner surface of the pipeline, assessment of their size. Profilemetry allows you to determine the patency of the pipeline for further diagnosis by EasyPig, EasyPig UT or other diagnostic equipment.

Analysis of the data obtained during the diagnosis is carried out by highly professional interpreter operators in a period of not more than 45 working days.